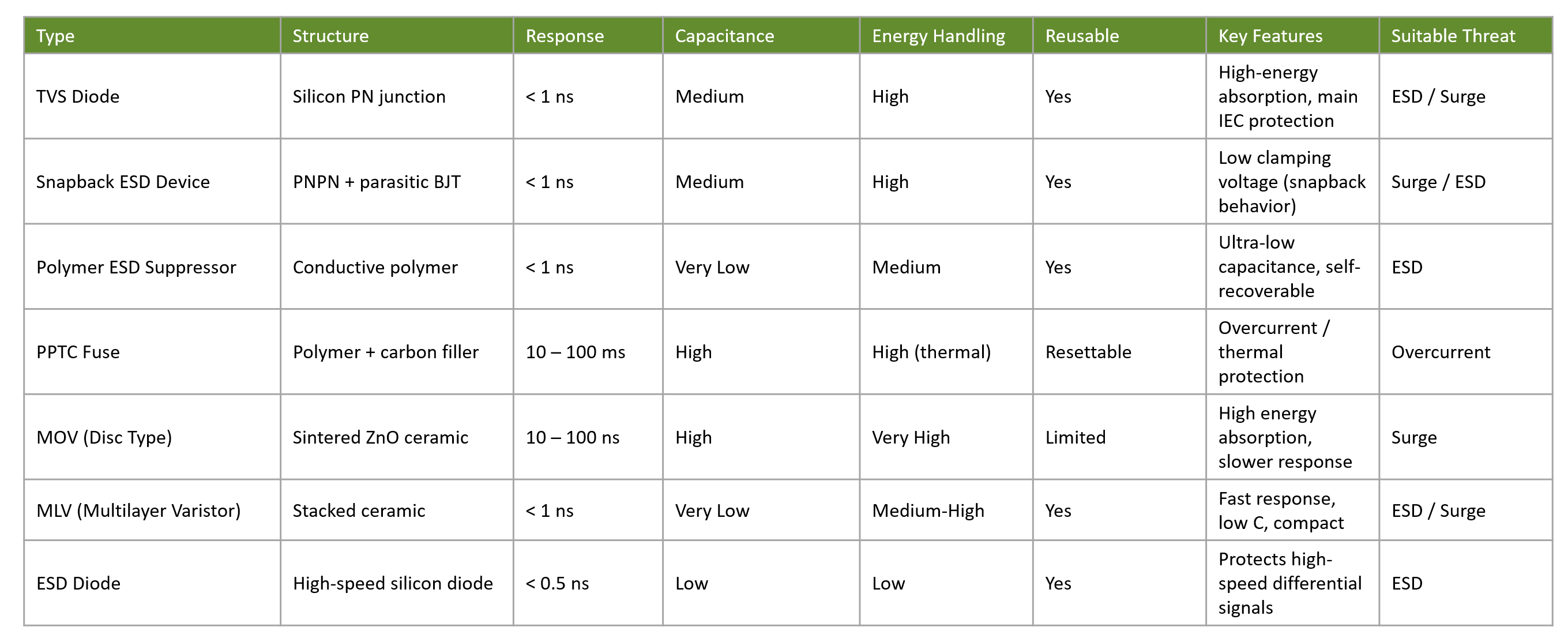

In modern electronic design, the continuous increase in data rates, power density, and circuit integration requires a precise balance between protection speed, robustness, and reliability.

Among all protection strategies, TVS Diodes and ESD Suppressors remain the most critical foundation for safeguarding sensitive ICs and signal interfaces from transient and electrostatic events.

While many suppliers provide similar protection components, Comchip Technology distinguishes itself with a comprehensive range of high-reliability TVS and ESD devices.

Comchip products are designed for ultra-fast response, stable and accurate clamping, and low-capacitance performance—ensuring signal integrity and long-term stability even in high-speed and high-density systems.

Through continuous innovation in materials, packaging, and process control, Comchip’s protection portfolio offers:

- Consistent performance across wide temperature and surge conditions

- Extended product lifetime with minimal leakage variation

- Compact and reliable surface-mount packages suitable for advanced designs

As the electronics industry continues to evolve toward higher performance and tighter integration,

Comchip remains a trusted partner in TVS and ESD protection—

offering the ideal balance of protection strength, cost efficiency, and long-term reliability for modern electronic systems.