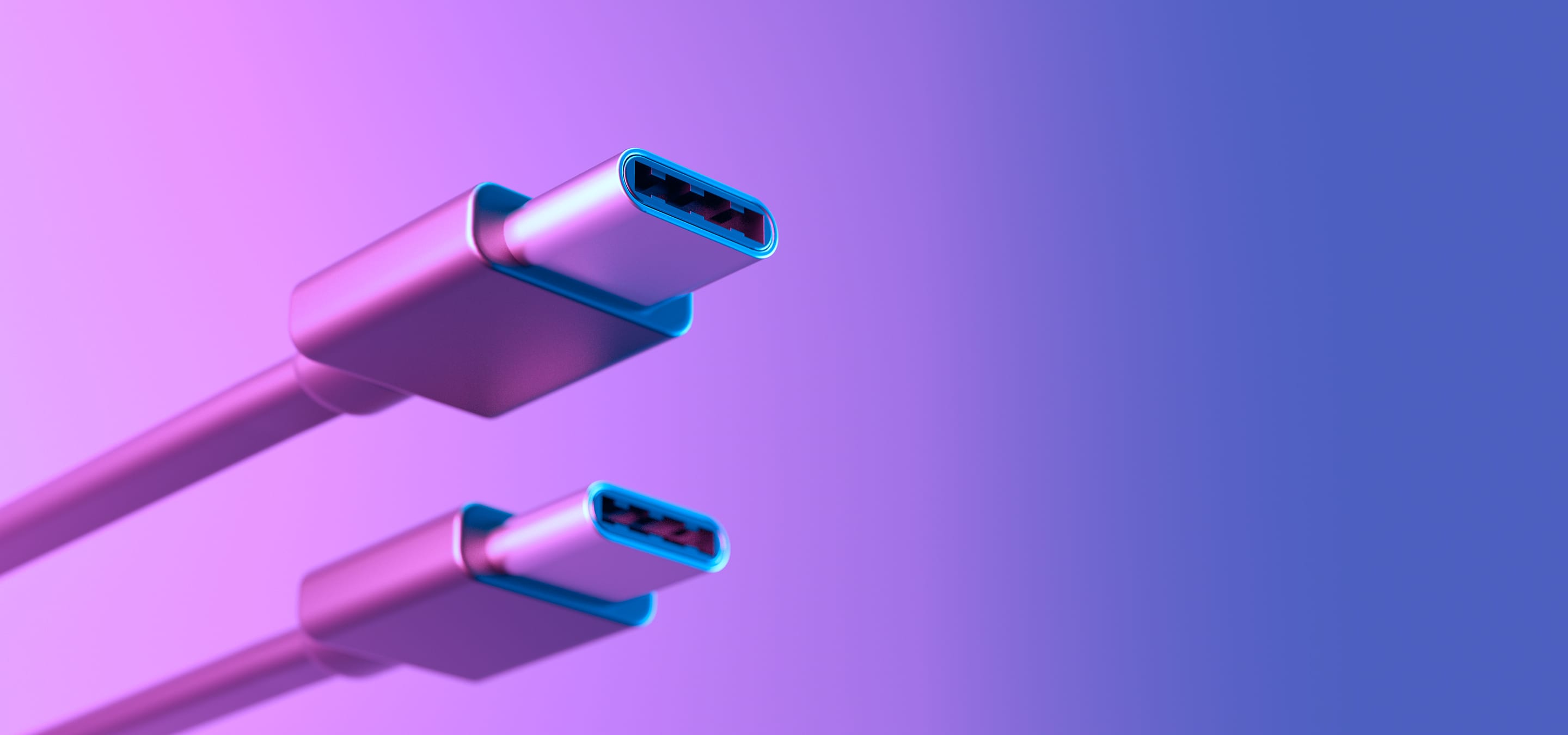

From Servers to Consumer Electronics.

Automotive Electronics

Automotive electronics include internal and external electronic control and power management systems, such as battery management, lighting, infotainment, and ADAS, ensuring driving safety and performance optimization.

Standard Schottky

CDBWLZ140L-HF

Low forward voltage, Designed for mounting on small surface, Extremely thin package, Low stored charge, Majority carrier conduction.

Industrial Control

Server Power

Industrial Sensors, Solar Inverters, Industrial Power Modules, Robotics & Automation Systems, Programmable Logic Controllers, PLCs, Motor Drivers & Inverters, Uninterruptible Power Supply, UPS.

Professionalism, Innovation, and Service Crafting Outstanding Packaging Technology

EXPLORE COMCHIP

Capability

We offers a comprehensive collection of technical documents, including datasheets, application notes, reliability reports, and certification files. Users can quickly download the required information to ensure optimal product selection and application.

About Comchip

Professional diode manufacturer, offering products including bridge rectifiers, high-efficiency fast rectifiers, switching diodes, Zener diodes, Schottky diodes, TVS diodes, and ESD surge absorbers. transistor MOSFET series products.

Privacy Policy

Welcome to the “COMCHIP Technology Website” (hereinafter referred to as "this Website").

To ensure that you can use the services and information provided by this Website with peace of mind, we hereby explain our Privacy Policy to protect your rights and interests. Please read the following carefully:

When using the contact form or other interactive features, the Website will retain information such as your name, email address, contact details, and the time of use.

For general browsing, the server will automatically record relevant data including your IP address, browser type, usage time, and clicked or viewed pages. These records are used internally for improving our services and will never be disclosed publicly.

If outsourcing is required for business purposes, this Website will ensure the outsourced party complies with confidentiality obligations and undergoes necessary supervision and auditing.

Exceptions to this rule include but are not limited to:

- With your written consent.

- As required by law.

- To prevent danger to you, life, body, liberty, or property.

- In cooperation with government agencies or academic institutions for statistical or academic research based on public interest, where the data has been processed so that no specific individual can be identified.

- When your behavior on the Website violates the Terms of Service or potentially harms the Website, other users, or any third party, and disclosure is necessary for identification, contact, or legal action.

- When it benefits your rights and interests.

- When a third party is commissioned to assist in collecting, processing, or using your personal data, this Website will exercise proper supervision and management of such third parties.